JarPro™ — Drillstring Jarring Analysis Software

JarPro Software Description

JarPro is a general-purpose 2D jarring analysis software program. It is used for performing various phases of oilfield jarring analysis, ranging from jar placement optimization to detailed time histories of jarring impact.

The program uses a systematic stress wave tracking approach to simulate the transmission of forces and motion in the drillstring during the jarring process. This approach enables JarPro to solve complex drillstring configurations efficiently using relatively simple inputs, thus facilitating its use by drilling engineers, rig personnel, and jarring tool manufacturers. Only basic jarring parameter selections and drillstring data are required during input, and a parametric range can be evaluated in a single run. All internal nodes and elements needed for the mathematical computations are automatically generated by the program. Data input can be in batch or interactive mode, and the format can be modified to your specifications.

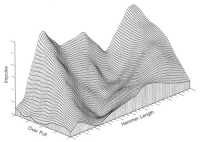

Output from JarPro consists of jarring parameter selections, the drillstring model, and a summary of the analysis results. Analytical results include the characteristics of jarring and, most importantly, the stuck point movements. Detailed time history of force, velocity, and displacement at any section in the drillstring is available for an in-depth jarring analysis. A plotting package is available for displaying the drillstring model, and to facilitate review of results from parametric studies or time history analyses.

Reducing the Cost of a Stuck Pipe Event

The loss of a bottom hole assembly due to a stuck pipe event is extremely costly. The cost goes well beyond the replacement cost of the expensive bottom hole assembly itself, including significant lost time, and various sidetracking expenses. Users of JarPro software can reduce the costs associated with a stuck pipe event by improving the selection and placement of jarring tools and accelerators.

Software Verification

The JarPro software program has undergone extensive verification through comparisons against closed-form solutions, manual computations, and more than 20 transient dynamic finite element runs. The program’s predictions have also been confirmed by users and drilling research organizations by performing a matrix of instrumented tests.

Summary Of JarPro Capabilities

The major JarPro capabilities are:

- Versatile two-dimensional drillstring modeling capabilities and ease of input

- Parametric analysis for jar placement, tripping force, stuck force, and stuck location

- Detailed time history of jarring forces, velocities, and displacements at user-selected locations

- Both jarring-up and jarring-down simulations

- Enhanced jar placement optimization options

- Special sections for accelerators and shock subs with nonlinear springs

- Modeling the effects of mud buoyancy, side wall friction, and pump-open at jar

- Material changes in a drillstring

- Single point or differential sticking simulation

- Plotting the analysis results and drillstring model

Contact us to know more about our JarPro software program.

JarPro Literature

Sample Pages from JarPro User’s Manual

This document includes an introduction to JarPro jarring analysis software, along with selected illustrations and examples of output plots.

JarPro Software Brochure

This two-page brochure provides an overview of the features and benefits of JarPro Jarring Analysis Software. It also provides example illustrations of the user interface.

Jarring Related Technical Papers Available by Mail

SPE/IADC #16155

A practical approach to jarring analysis was presented in this paper to assist application engineers in jar section and jar placement optimization.

SPE/IADC #13446

This paper presented a detailed transient dynamic analysis of the drillstring under jarring operations. A finite element model was used in the study to predict the dynamic response of a drillstring to jarring.

Sample JarPro Software Input Pages