BDRP Seals (Figure 1) are Plastic Lined rotary seals that were developed to provide hydrodynamic interfacial lubrication in either direction of differential pressure and either direction of rotation. This design goal was achieved by providing hydrodynamic waves that are capable of pumping lubricant from an unpressurized lubricant reservoir, through the dynamic sealing interface, and into a high-pressure fluid. One target application of the BDRP Seal™ is oilfield rotary control devices (RCDs) with unpressurized lubricant reservoirs. In RCDs, BDRP Seals are intended to be used in conjunction with an outboard barrier seal, with the barrier lubricant region between the seals pressure-balanced to the well pressure.

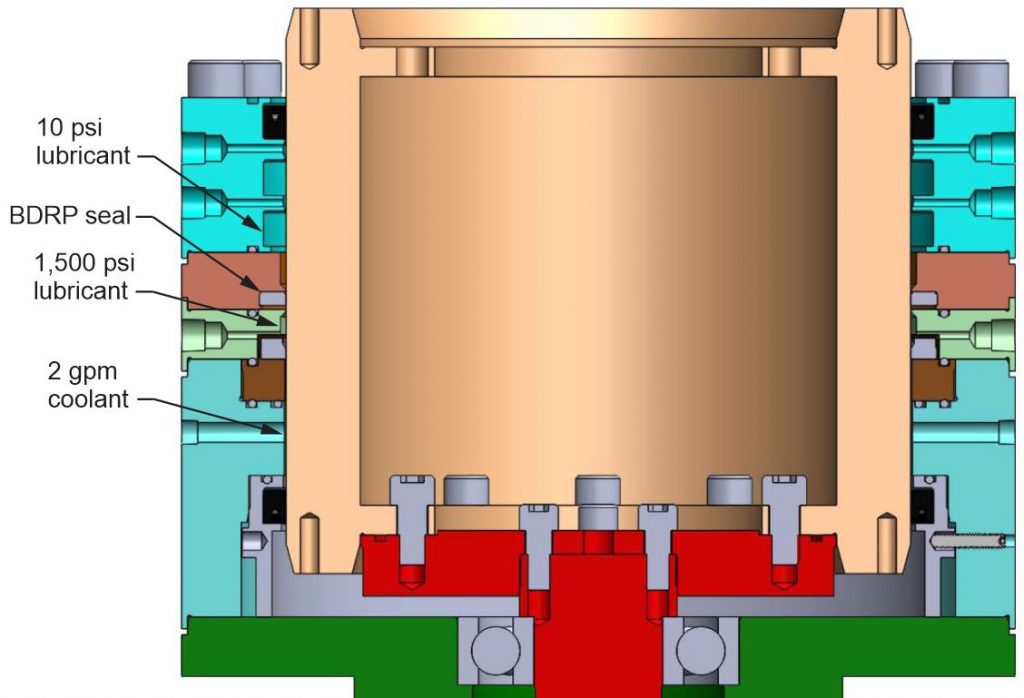

With RCD applications in mind, Kalsi Engineering tested a 10.49-inch PN 717-1-318 seal at 75 rpm and 1,500 psi. The unpressurized seal lubricant was an ISO 320 viscosity grade synthetic hydrocarbon lubricant. The test setup is shown in Figure 2. The BDRP Seal was installed with the waves facing upward, as it would be oriented in an RCD to expose the waves to the unpressurized bearing lubricant. The nominal radial extrusion gap above the BDRP Seal was 0.010-inch. The lubricant above the BDRP Seal was supplied at about 10 psi, to assure lubricant flow through constricted lubricant supply tubing. The chamber below the BDRP Seal was pressurized to 1,500 psi, simulating the barrier lubricant region of an RCD with a barrier seal. The lower end of the pressurized chamber was sealed with a 682-series Plastic Lined rotary shaft seal. Coolant was circulated below the 682-series seal to simulate the cooling an RCD mandrel receives from exposure to the drilling fluid surrounding the lower end of the mandrel. The coolant circulation rate was about 2 gpm, and the coolant inlet temperature was typically about 90°F.

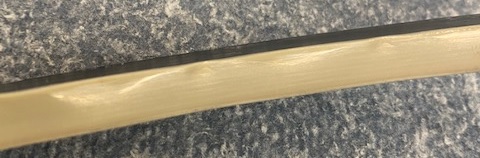

We experienced fixture problems at 103 hours. When the fixture was disassembled for repair, the BDRP Seal was inspected and found to be in good condition (Figure 3). After correcting the fixture problem, we reassembled the fixture with the same BDRP Seal and continued testing under the same conditions for an additional 148 hours. After 251 total hours of operation at 75 rpm and 1,500 psi, the test seal was still functional and in good condition (Figure 4). Throughout the testing, hydrodynamic waves on the BDRP Seal pumped a lubricant film from the low pressure chamber, through the dynamic sealing interface, and into the high pressure chamber. The low friction resulting from this interfacial lubrication allowed the seal to withstand the severe operating conditions with minimal wear.

For confirmation of results, a second test was performed at 75 rpm and 1,500 psi with a new BDRP Seal. The test was shut down at 200 hours to inspect the test seal, which was still in excellent condition (Figure 5). Other testing of the 10.49-inch BDRP Seal has been performed with 1,000 psi at 170 rpm. Contact our engineering staff to discuss how to take advantage of this exciting new high-performance seal design in your RCD product line.