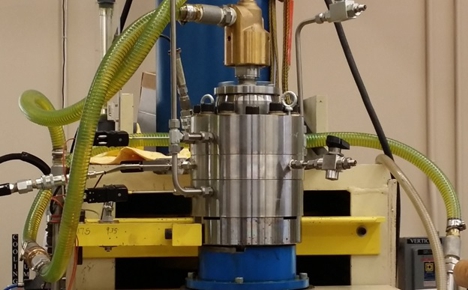

A new video shows how easy it is to assemble a high pressure washpipe assembly that incorporates our patented floating metal backup rings and hydrodynamic rotary seals. The backup rings are radially pressure balanced and axially force balanced. The radial pressure balance makes them relatively immune to pressure induced deformation, which allows for a more consistent extrusion gap clearance for the mating rotary seal. The axial force balance allows the backup ring to float laterally to align on the washpipe. This combination of features allows the use of the smallest practicable extrusion gap clearance, which reduces pressure-induced damage to the rotary seal. These features and benefits are explained, as the relevant components are assembled.

The key to easy assembly is our stacked housing arrangement, which is readily adaptable to various rotating equipment, such as rotary control devices (RCDs), side entry cement swivels, and other high pressure side port swivels. One thing that facilitates assembly is the elimination of difficult-to-assemble, failure-prone radially sealing O-rings. Another factor is the elimination of the conventional pressure housing, which means that no components are required to have a tight fit with the bore of a pressure housing.

For more information about the high pressure washpipe assembly, contact our staff. See Section E of the handbook for tips on how to use our stacked housing, floating backup ring arrangement in extreme pressure side entry swivels and oilfield cement heads.