How are Kalsi Seals used in rotating control devices?

Introduction to rotating control devices

A rotating control device (RCD) is a side exit swivel that establishes a seal with the rotating drillstring of an oil well to contain well pressure and divert the drilling fluid that is returning to the surface. One or more large sealing elements establish the seal with the drillstring, and these sealing elements are attached to a bearing-guided mandrel so that the sealing elements rotate with the drillstring. Kalsi-brand rotary seals are used to seal between the rotating mandrel and the housing that locates the bearings. Lubricant is provided to lubricate the seals and bearings.

Basic types of rotating control devices

RCDs can be broadly classified into two categories: lubricant overpressure RCDs and lubricant underpressure RCDs. In a lubricant overpressure RCD, the seal lubricant is maintained at a pressure that is several hundred psi greater than the pressure of the drilling fluid. In a lubricant underpressure RCD, the pressure of the seal lubricant is significantly less than the pressure of the drilling fluid and is typically at or near atmospheric pressure.

A lubricant overpressure RCD is significantly more expensive than a lubricant underpressure RCD because of the additional equipment that is necessary to actively control the pressure of the seal lubricant. Lubricant overpressure RCDs have a distinct performance advantage, because they allow the use of Kalsi-brand rotary seal designs that inherently have more pressure capacity. Each type of RCD has its place in the industry, as determined by economics and performance requirements.

How Kalsi Seals are used in lubricant overpressure RCDs

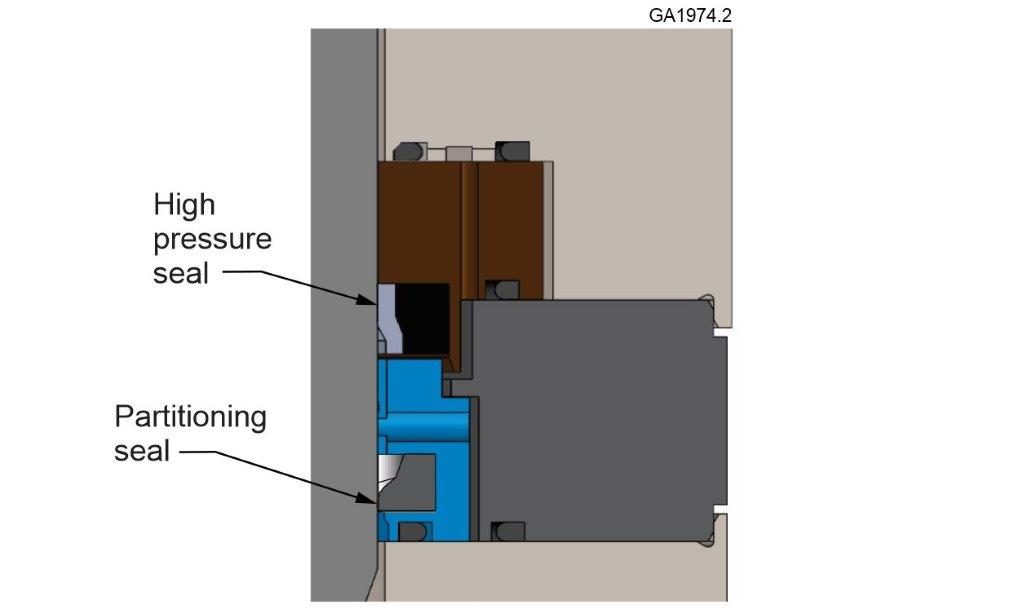

In a lubricant overpressure RCD, a pair of rotary seals are used to contain the pressure of the seal lubricant. The lower rotary seal partitions the drilling fluid from the seal lubricant, and the upper rotary seal retains the pressure of the seal lubricant. Each rotary seal has hydrodynamic waves that face the pressurized lubricant and force a film of lubricant into the dynamic sealing interface between the seal and the mandrel when the mandrel rotates. This interfacial lubrication reduces friction, wear, and seal generated heat, and promotes long operational life. Because the hydrodynamic waves are on the higher-pressure side of the rotary seals, there is no tendency for the waves to collapse because of differential pressure. This wave configuration is opposite to the configuration used in lubricant underpressure RCDS and is why the rotary seals used in overpressure RCDs can be designed to have higher pressure capacity than rotary seals used in lubricant underpressure RCDs. In a lubricant overpressure RCD, the lower seal is typically made from a single elastomer, while the upper rotary seal can have a harder elastomer or plastic liner that provides extra pressure capacity.

The placement of the rotary seals in a lubricant overpressure RCD is optional. In the traditional arrangement, the lower seal is positioned below the bearings, and the pressure-retaining upper seal is placed above the bearings. This has the advantage of allowing the seals to utilize the bearing lubricant but has the disadvantage of pressurizing and expanding the bearing housing. This housing expansion results less precise control of the mandrel, creating less favorable conditions for the rotary seals by permitting more lateral deflection and runout that requires larger mandrel-to-housing extrusion gaps.

As an alternative to the traditional arrangement, both rotary seals can be placed below the bearings, isolating the bearing housing from lubricant pressure and thereby allowing more precise mandrel control. This implementation also involves tradeoffs, in terms of overall system complexity, but provides the advantage of allowing both seal grooves to be machined directly into the bearing housing, which provides optimum concentricity between the bearing mounting bore and the bore that defines the extrusion gap clearance with the mandrel.

When the goal is to achieve the highest-pressure capacity and longest seal life, the rotary seals of an RCD can be mounted in seal carriers that align on the mandrel and move laterally to follow lateral shaft deflection and runout (see here, and here). Such carriers allow a small extrusion gap clearance to be used for the pressure retaining seals, without risk of seal-damaging metal-to-metal contact at the extrusion gap. The small extrusion gap results in less pressure-related seal stress, and significantly higher seal pressure capacity. Such carriers also result in less relative radial motion at the lower seal, which improves the ability of the lower seal to resist drilling fluid-related abrasive wear.

To achieve the highest dynamic pressure capacity, the lubricant pressure can be divided between two pressure retaining seals, so that each is only exposed to half of the total lubricant pressure. This is referred to as pressure staging and requires a minimum of three rotary seals. For more information on using Kalsi-brand rotary seals in lubricant overpressure RCDs, see this chapter from our seal handbook, and contact our technical support personnel with your questions.

How Kalsi Seals are used in lubricant underpressure RCDs

The Kalsi Seal used in lubricant underpressure RCDs is called a KLS Seal. It is a plastic-reinforced spring-loaded lip seal that has the hydrodynamic waves on the low-pressure end of the seal. The recommended practice is to position two KLS® Seals below the bearings, and to pressure-balance the lubricant between the seals to the pressure of the drilling fluid using small pressure-balancing pistons. This allows the upper seal to retain pressure in a clean lubricated environment and allows the lower seal to exclude abrasives in the absence of significant differential pressure. This arrangement provides redundancy, where if either seal fails, the remaining seal assumes both the pressure retention and abrasive exclusion functions. For additional information about using KLS seals in lubricant underpressure RCDs, see this handbook chapter, and contact us for answers to your questions.

Should an RCD be supplied with active cooling?

The bearings in RCDs support significant thrust loads and generate considerable heat. The rotary seals are exposed to significant surface speeds and pressures, and likewise generate considerable heat. RCDs are being challenged to operate at higher rotary speeds, and as speed increases the heat generated by the seals and bearings increases at a rate that is higher than the rate of speed increase. The seals are made from polymers that lose strength and other important material properties as temperature increases. Lubricant circulation helps to reduce seal temperature, which promotes longer seal life and higher pressure capacity.