Core Capabilities and Services

- Structural, fluid, and thermal analysis

- Elastomer FEA

- Design and product development

- Mechanical and flow testing

- Tribology… friction, wear, and lubrication

- Valve technology

- Seal technology

- Failure analysis

- AOV/MOV Services

- MOV Actuator Test Stand (Torque & Thrust)

- MOV Actuator Test Stand (Torque Only)

Kalsi Blog (View All)

Remembering Professor Metcalfe

We at Kalsi Engineering are very saddened by the news of the passing of Professor Metcalfe. For over two decades he mentored four of Kalsi’s engineers during their graduate research.

Ralph William Metcalfe

Posted by Crowder Funeral Home — Clear Lake

Ralph William Metcalfe, 78, of Seabrook, Texas, died peacefully on June 19, 2025, with much love and support around him. He was born on October 15, 1946, in Dallas, Oregon, and grew up in Seattle, Washington where his father was an engineer at Boeing. He graduated from the University of Washington, where he majored in Mathematics, and then went to graduate school at M.I.T. where he received his M.S. and PhD in Applied Mathematics.

After M.I.T., Ralph worked as a research scientist with the fluid flow research group at Flow Research in Seattle, where his research focused on computational fluid dynamics. In 1987 he came to the

Rotary Seals

High Pressure Shaft Seals

Consulting Engineering Services

Kalsi Engineering, Inc., a high technology firm, was founded in 1978 to provide consulting engineering services in the areas of research and development, design, analysis, and testing of mechanical equipment and structures. Our facilities are located in Sugar Land, Texas, approximately 17 miles from downtown Houston and easily accessible from the airports.

Our Clients

Kalsi Engineering has a diversified client base that includes equipment manufacturers, oilfield service companies, petrochemical plants, nuclear power plants, aerospace engineering companies, architect/engineers, industry research organizations, and government agencies. In addition to serving individual clients, we have successfully completed many joint-industry group-sponsored projects.

Our Products

In addition to providing consulting engineering services, Kalsi Engineering offers rotary seal and software product lines that were originally developed to solve difficult problems associated with energy production. Our patented rotary seals are the result of our pioneering research in hydrodynamic lubrication, making us a leading oilfield rotary seal manufacturer.

Kalsi Seals

Kalsi Seals® are a family of patented, one-piece rotary seals that provide hydrodynamic lubrication to minimize seal and shaft wear, and to accommodate high differential pressure.

Read More

Kalsi Software

Our suite of engineering software began with JarPro™ jarring analysis software, which is used to reduce the costs associated with a stuck drillstring by optimizing jarring tool placement. KVAP®, CVAP® and LiFE® are state-of-the art software applications that are widely used to evaluate critical valve and actuator issues in nuclear power plants.

Read More

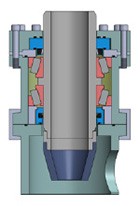

BDRP Kalsi Seals™

Traditional Kalsi Seals require the lubricant pressure to be balanced to or higher than the environment pressure. The revolutionary BDRP™ Rotary Shaft Seals were developed for applications where the pressure of the seal lubricant may be up to 1,500 psi (10.34 MPa) less than the pressure on the opposite side of the seal. The ability to handle pressure in either direction and significant speed makes the BDRP a good candidate as a hydraulic swivel or rotating control device (RCD) seal.

Read More

KLS High Pressure Lip Seals

KLS® spring-loaded lip seals are used to retain a pressurized non-abrasive fluid. They were designed and successfully tested for service conditions where the pressure acting from the spring side of the seal is up to 1,500 psi greater than the pressure of the seal lubricant. The high level of performance is made possible by the interfacial lubrication that is provided by a patented hydrodynamic wave geometry on the low pressure end of this innovative rotary shaft seal.

Read More

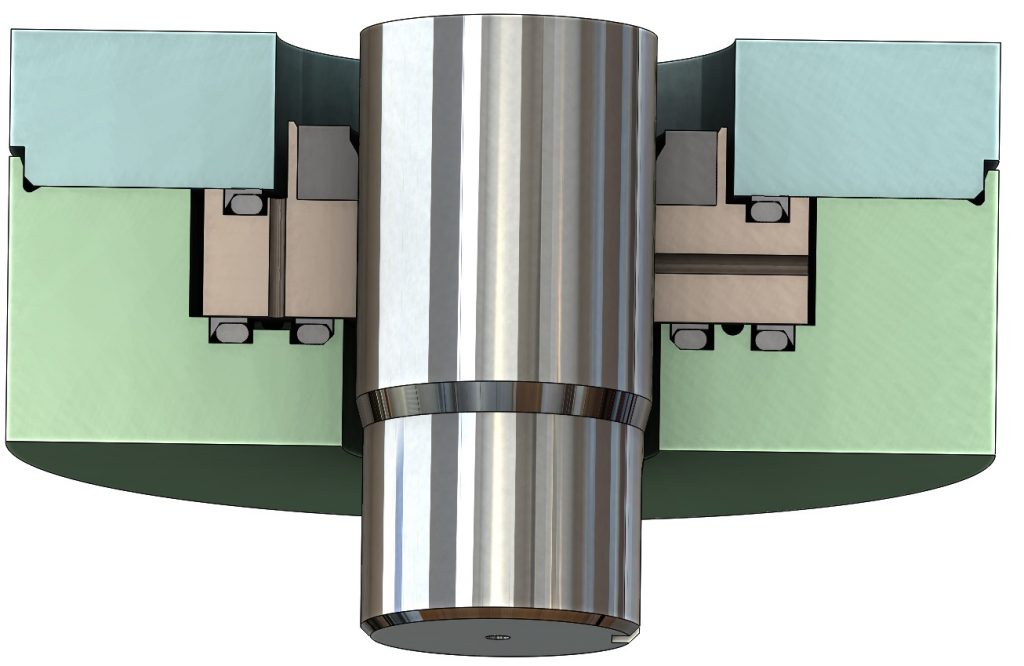

Axially Force Balanced, Laterally Floating Backup Rings

The patented floating backup ring arrangements are axially force balanced, and radially pressure balanced. These features allow the smallest practical extrusion gap to be used, while accommodating shaft runout and misalignment. By minimizing the extrusion gap, the rotary seals can seal higher pressures for longer periods of time. Floating backup rings are applicable to many types of equipment, including rotating control devices (RCD), oilfield washpipe assemblies, sideport swivels and hydraulic swivels.

Read More

Kalsi Seals for Rotating Control Devices (RCDs)

A rotating control device (RCD) reduces formation damage in oilwell drilling by maintaining the pressure of the annular fluid column of drilling mud at a pressure below, or comparable to, that of the reservoir. Early versions of Kalsi-brand rotary seals began to be used in RCDs in 1991. Since then, several advances in technology enable our seals to operate in more adverse RCD sealing conditions, including higher pressure, higher speed, less cooling, lower viscosity lubricants, and less complicated lubricant supplies.

Read More

KALSI SEALS HANDBOOK™

Our handbook provides detailed information about selecting Kalsi-brand rotary shaft seals, and implementing them in pressure retaining and fluid separation applications, with a focus on oilfield applications. It consists of individually revisable chapters. This format streamlines the publication process, so we can provide the most up to date information on our rotary shaft seal technology. Written by our senior staff members, it presents the collective wisdom of many decades of experience. Topics covered by the handbook include product selection, seal material characteristics, seal performance characteristics, assembly considerations, and machine design practices.

Read More

FLOW LOOP

Our modular water flow loop is rapidly reconfigurable to different piping configurations. It was developed to evaluate 2”-10” valves, and has a pressure capacity of 270 psig. The flow capacity is 2,700 gpm, which correlates to 30 feet per second with 6” piping. The meter run provides a flow measurement accuracy of ± 0.5 percent. A variety of temperature, pressure, load, and displacement transducers are available for use with our high speed data acquisition system.

Read More